Shandilya Energy System

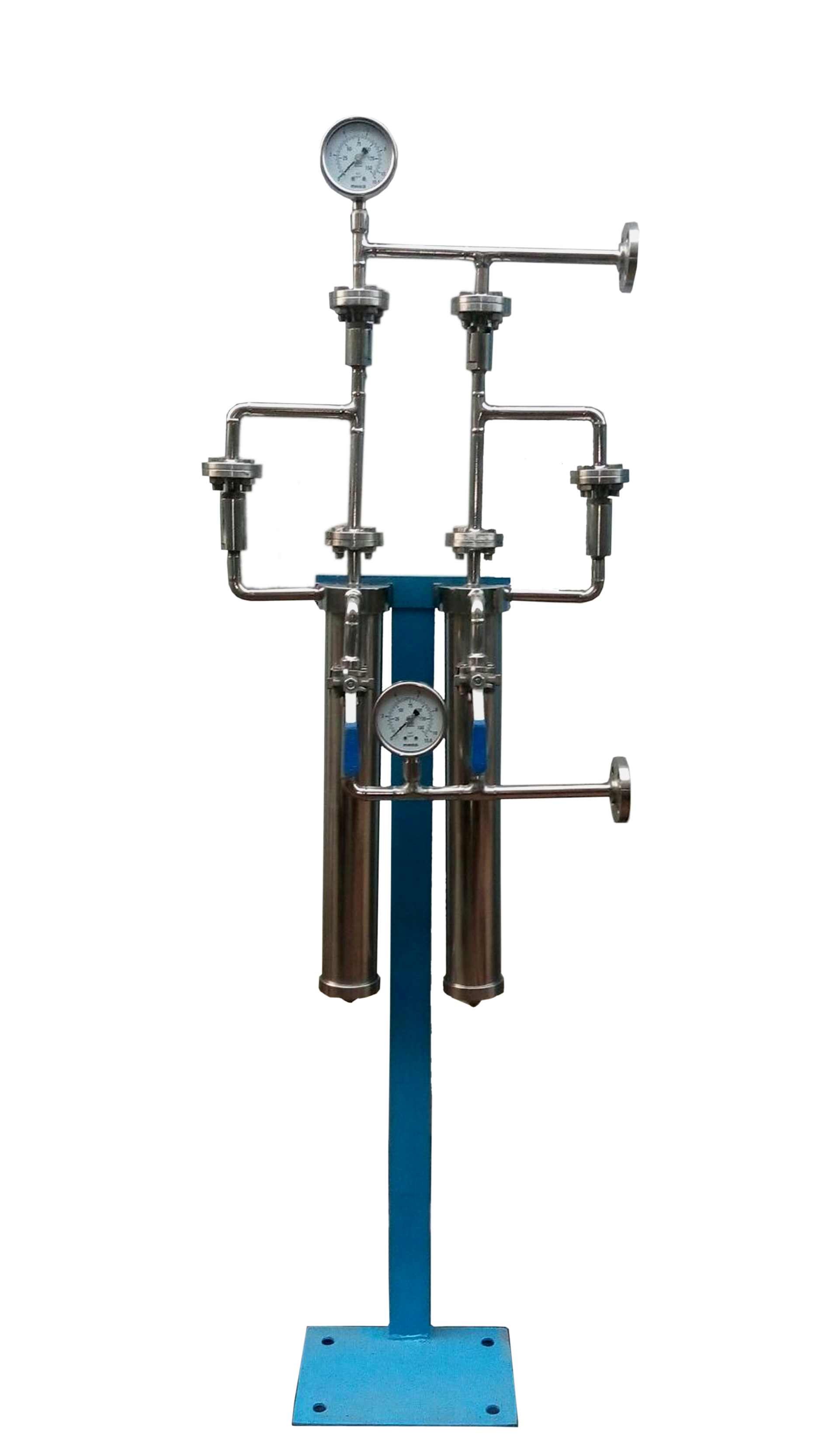

Manufacturer of Natural Draft Air Finned Cooler For Mechanical Seal, API Plan 52, 53A and 53C, Magnetic Level Indicator, Water filter For Mechanical Seals

|

Shandilya Energy System

|

|

Manufacturer of Natural Draft Air Finned Cooler For Mechanical Seal, API Plan 52, 53A and 53C, Magnetic Level Indicator, Water filter For Mechanical Seals |

|

|

|

|

|

|

||||||

|

Benefits of Enhanced Air Finned Cooler... Reliability: Any equipment which depends on the reliability of other equipment is not reliable or less reliable. Shandilya’s Air Finned Cooler cools the product with natural draft. It does not have any moving parts, needs no external power source. Shandilya’s Air Finned Cooler does not depend on the cooling water, therefore Risk of shut down due to poor quality/ quantity of water is eliminated. Direct saving Cost of Water: With Air Fin Coolers no water is required hence cost of water is saved. To get desired amount of cooling normally for water-cooled heat exchangers 40 to 50 lpm water is required. @ Rs 5 per cubic meter approximate saving will be about Rs. 110000/- per year. Cost of circulation of water: The energy spent in water circulation in is saved. On an average about 0.5kW of power is required for recirculation of water in each cooling circuit. @ Rs 4.5 per kw the power cost would be Rs.19710/- Preventive Maintenance: Water causes scaling problem, and due to scaling, temperature to the seal goes up, the pump needs to be taken for removal of scale. Cost of removal of scale and loss of production is saved with Air Fin Coolers. Cost of each shut down is between Rs. 50,000/- to Rs. 1, 50,000/- (depends on criticality and cost of the product.) Shut down Maintenance: If seal fails because of poor cooling in addition to the production and maintenance loss, cost of replacement seal components add to the loss. The cost incurred varies between Rs. 75,000/- to Rs. 5, 00,000/- depending on the seal size and spares consumed. Indirect saving Fouling: In absence of water, no scaling can take place. Because of scaling heat transfer gets reduced, hence either water consumption goes up or temperature in seal area goes up which reduces the seal life. Better circulation of flushing fluid: In absence of coil, friction loss reduces hence there is better circulation of flushing liquid. The seal will be more comfortable with increased amount of flushing liquid, as there is no friction. Cooling Tower Water Contamination: in the process of scale removal the water cooled heat exchanger tube gets eroded / corroded and becomes week and some time may get punctured. Identification of leaking cooler takes enormous time. Also entire cooling tower water needs to be drained. In Shandilya’s Air Cooler such possibility does not arise because of absence of water. Fire Hazard: In the event of seal failure in case of API Plan 02, the hot liquid leak to the atmosphere. If it is at the self ignition temperature, it catches fire. In API Plan 21 cool product reaches to the seal as long as the pump is running. Therefore in the event of leakage only cool product will come out of the stuffing box and no chance of catching fire.

|

||||||

|

|

||||||

|

||||||