Shandilya Energy Systems Pvt. Ltd.

Manufacturer of Natural Draft Air Finned Cooler For Mechanical Seal, API Plan 52, 53A and 53C, Magnetic Level Indicator, Water filter For Mechanical Seals

|

Shandilya Energy Systems Pvt. Ltd.

|

|

Manufacturer of Natural Draft Air Finned Cooler For Mechanical Seal, API Plan 52, 53A and 53C, Magnetic Level Indicator, Water filter For Mechanical Seals |

|

|

|

|

|

|

||||||

|

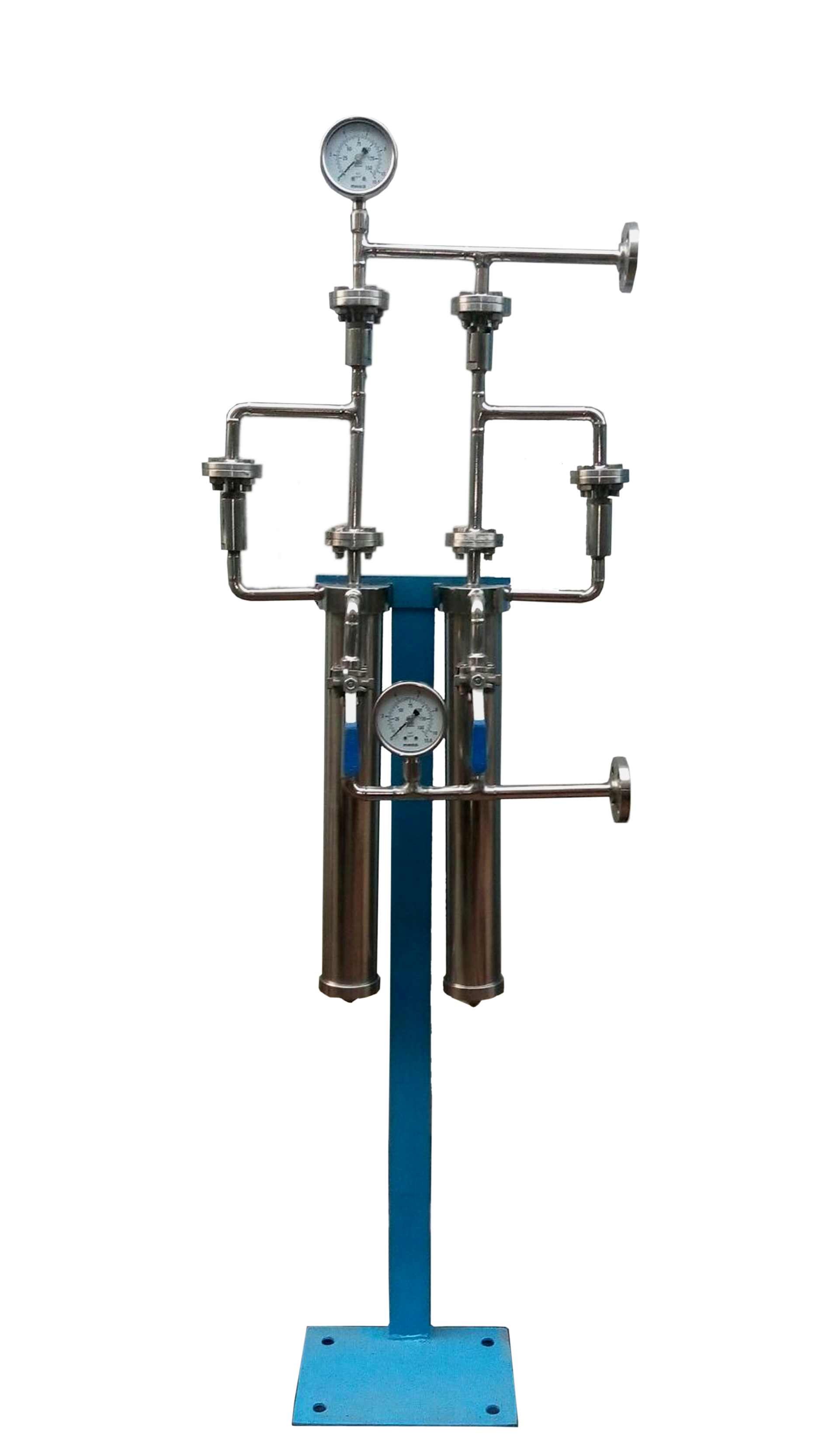

API Plan 53C ... API Plan 53 is used for the applications where no fluid leakage to atmosphere is permitted. The Plan 53 is for double seal. During operation an internal pumping ring provides circulation. In API Plan 53C external pressurised barrier fluid reservoir provides fluid to the seal chamber. It is normally used for the applications where no fluid leakage to atmosphere is permitted. The barrier fluid must be pressurised to about 1.0 to 2 kg/cm2 above the pump seal chamber pressure. Inner seal leakage (if any) will be barrier fluid into the product and no process fluid will be allowed to leak in to barrier fluid area. Plan 53C is a dual pressurized system that eliminates the use of gas for the pressurization through the use of a piston reservoir. Barrier liquid is stored on the top side of the piston, which travels the length of the vessel dependent upon the change in barrier liquid volume. A reference pressure, typically taken form the seal chamber, is provided on the bottom of the piston. ‘O’ ring is provided on the piston to separate barrier fluid and process fluid. The difference in area on either side of the piston creates a 10% increase in the barrier liquid pressure across a full range of operating pressure. This system is ideal for the applications that have fluctuating pressure. External piping provides fluid for the outer seal of a pressurized dual seal arrangement. Reference line from the seal chamber to a piston accumulator provides pressure to the circulation system. Flow is maintained by an internal pumping ring. Heat is removed from the circulation system by an air-cooled or water-cooled heat exchanger. The piston accumulator (an external reservoir that contains a limited amount of fully de-aerated clean barrier liquid) pressurizes the barrier fluid based on the reference line providing a tracking system to maintain barrier pressure above seal chamber pressure. This system is ideal for applications that have fluctuating pressures and higher pressure in stuffing box chamber. Used with dual pressurized seals to isolate process fluid (that is usually hazardous /toxic in nature).

|

||||||

|

|

||||||

|

||||||